WOOD PROCESSING AND WOODWORKING

Whatever branch your company covers within the industry of wood processing and woodworking, wood as a natural resource needs to be grown and harvested first. Second, logs go through the initial woodworking process, for instance peeling or debarking. Next, wood is cut in sawmills and being processed into valuable products, from semi-final products to consumer products. Every step in the process adds value to the woodworking chain.

Wood processing includes various branches such as timber processing, sawmills, timber merchants, carpenters, roundwood producers, lumber yards, construction companies, and companies in the paper and cardboard industry.

Bezner-Oswald designs and manufactures machinery especially for organizations who process logs into semi-final products. We distinguish:

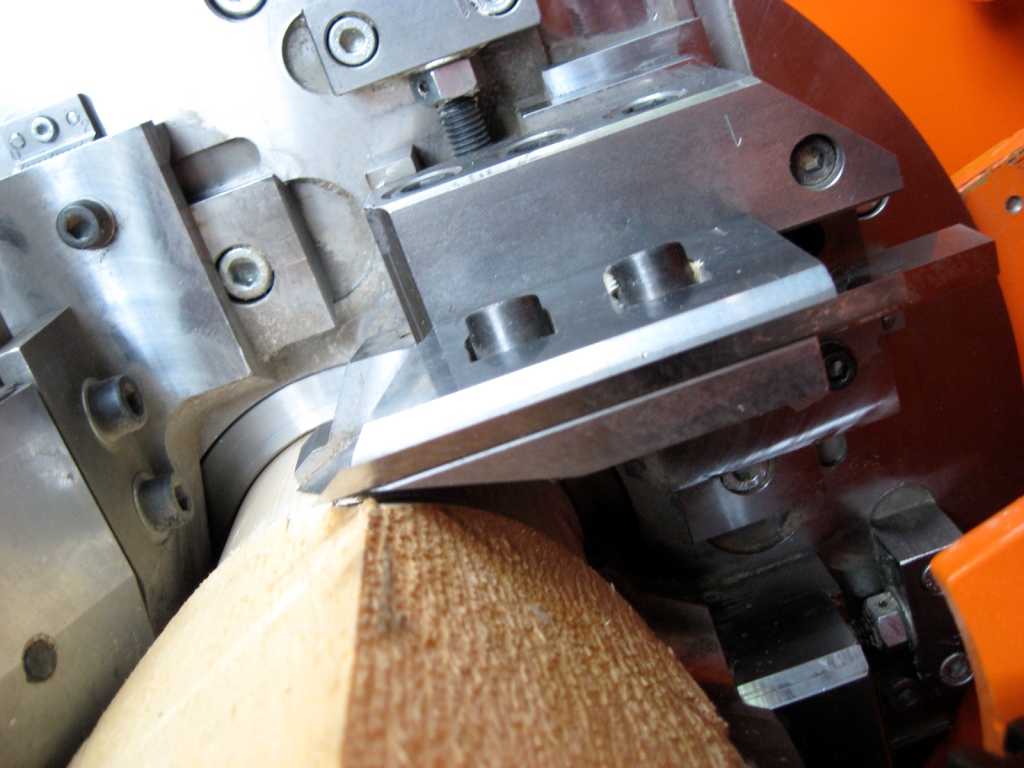

Timber | every activity to transform logs into wood ready for further processing. Think of machines for peeling, rounding, profiling, chamfering and pointing, and sawing.

Timber residues | every activity to maximize the application of lumber residues. Sawmill residue material is further processed in, among others, wood fiber products, OSB (oriented strand board), biomass, firewood. Think of machines for conveying and screens for sorting and batching wood chips, shavings, and sawdust.

If your industry has not been mentioned above, this does not mean we cannot help you. Please let us know any question you may have about your particular company or application. Contact us today and find out how we can help you.

Feel free to contact us directly:

Sales team

E: info@bezner-oswald.com

T: +49 (0) 5231 308 710

Know what you want? Fill out our contact form:

German

German French

French